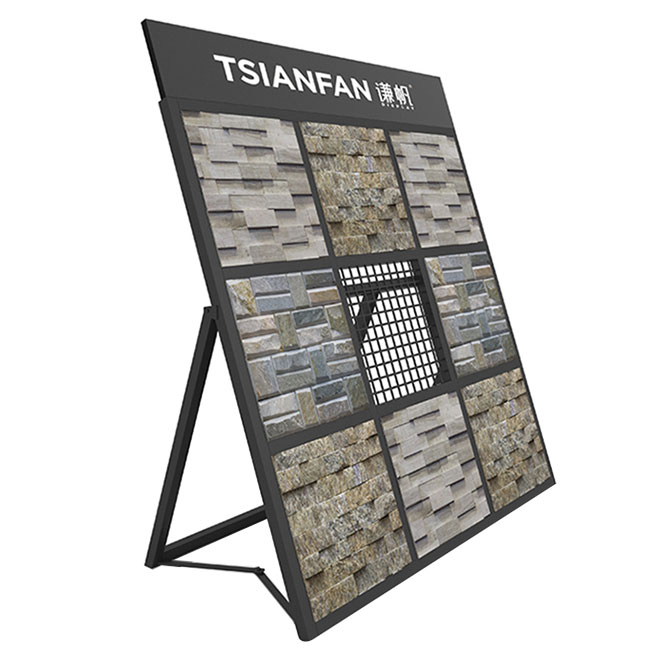

The tile display rack design should ensure that the exhibition hall has sufficient space and floor area. Make full use of the three-dimensional dimensions of plane space and vertical space. Design distinctive exhibition halls and shelves. More convenient for customers to watch. Reduce the difficulty of placing tile samples in business sales.

We all know that the price of facades in Xiamen is indeed relatively expensive. For the ceramic tile sales owner, how to improve the display effect of the ceramic tile display rack is a very important thing. The space to be used here is to place knowledge. Fortunately, I have completed a subject in space utilization at the university. Today, I will share the scientific use of space in the tile store.

The plane area is so large. What if the utilization rate is increased? In fact, we can use three sides: (three-dimensional space, wall space and ground space) With these three aspects well planned, your exhibition hall placement cannot be worse.

Wall space: This concept is easier to understand. It is only necessary to lay the wall display shelf on the remaining wall surface. It should be noted here that the inclination should not be too large, and the large tile should be placed in a low position, and the small plate should not exceed the horizontal position of the human sight. People now generally have cervical spondylosis. If the angle is too high, most people are unwilling to see it for too long, and it also hurts the cervical spine.

Three-dimensional space: According to the actual height of the store, purchase a small display area with a sufficient height of the display rack. Such a display rack can use a three-dimensional space with high utilization. Or more tile samples are placed. However, it is important to note that the bottom plate of the display rack must be stable or directly fixed.

Floor space: My suggestion is to place it in a “back” shape. It can be placed on the back of a column. The zigzag shape can make the best use of the floor space while taking into account the tiles on the wall space. Also the customer’s take and watch.

If these three spaces encounter conflicts, for example, the space display rack blocks the customer’s view of the wall display rack. Then we need to operate according to specific circumstances. Take all factors into consideration and work out a vantage point that best fits each space display stand.

What are the standards for acceptance of stone showcases? Now the demand for stone showcases is increasing, and the number of stone showcase showcases is increasing. But when we purchase showcases, how do we go about acceptance? This problem may lead to purchase of showcases The people are stumped because they really don’t know how to carry out the acceptance of the showcase. In response to this question, I will give you a detailed introduction below.

The first step: confirm whether the quantity of the display cabinet received is in accordance with the order delivery, various accessories are complete, the color is on the sample, and the packaging meets the requirements.

Step 2: Testing the overall installation accuracy of the showcase

1.The vertical deviation of the showcase piece is not more than 10mm;

2.The height deviation of beams on the same layer is ± 10mm;

3.The deviation of the center distance between the bottoms of the columns of adjacent showcases is ± 2mm;

4.The deviation of the display cabinets in the same lane and the same row is not greater than 5mm;

The third step: display cabinet manufacturing accuracy test

1. The column is punched and rolled by imported CNC machine tools, and the error of the head and tail holes is ± 2mm;

2. At full load, the inside and outside curvature of the column should be less than H / 1000, and the load deflection of the beam should be less than L / 250;

3.The rigidity and strength of the showcase conform to the machinery industry standard GB / 5323-91;

4. Showcase welding process is performed in accordance with national standards. There is no desoldering or virtual welding. Each welding part is manually removed with welding slag and spatter.

Step 4: Surface treatment process

Black blank-remove surface dirt-chemical rust removal-phosphating-spraying-leveling curing-packaging inspection storage, coating thickness 60 microns.

Mar-07-2022